Revolutionising Diamond Traceability: Sarine and Rubel & Ménasché Unveil New Data-Backed Solution for Melee Diamonds

Hod Hasharon (Israel), 2 October 2023 – Singapore Exchange Mainboard (SGX) and Tel-Aviv (TASE) listed,Sarine Technologies Ltd (“Sarine” and along with its subsidiaries “the Group”) (U77:SI; SARN.TA), a worldwide leader in the development, manufacturing, marketing and sale of precision technology products for the evaluation, planning, processing, measurement, grading and trading of diamonds and gems, is pleased to announce a major breakthrough supporting the expanding need for transparency in the diamond industry. In collaboration with Rubel & Ménasché, a distinguished French Maison for high-end jewellery, we have developed a new completely data-backed verifiable traceability solution for melee diamonds, the small yet precious stones used extensively in jewellery settings.

Rubel & Ménasché brought extensive knowledge and experience in diamond supply monitoring and traceability processes. Together with Sarine’s proven cutting-edge traceability technologies, we are delighted to announce the creation of a revolutionary method to track melee diamonds, setting new industry standards.

The innovative solution addresses the essential need for the verifiable traceability of melee diamonds, which, though smaller, constitute the bulk of the diamonds set in luxury diamond jewelry. To guarantee responsible sourcing of melee and enhance consumer confidence, we specifically aim to enhance the certainty regarding the diamonds’ provenance, by establishing a verifiable documented link between the rough diamonds and their origin and the polished stones used in the jewelry piece. Sarine, already known for its proven traceability of larger diamonds, now extends this capability to small stones in large quantities, further advancing the industry’s transparency and traceability efforts.

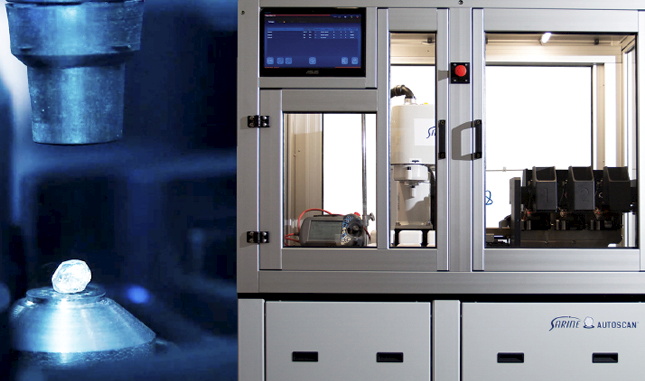

The solution is based on the actual measurement of the diamonds in their rough stage, continuing on through the polishing activities, until fully polished. Parcels containing large quantities of diamonds undergo initial registration on Sarine’s new high-productivity Autoscan Plus system. This is followed by planning and quality control measurements throughout the manufacturing process. The process concludes with the verification of the polished diamonds. This process is based on the same technologies used for larger diamonds in Sarine’s well-established Journey™ traceability paradigm, with the necessary adjustments to scale up for the larger quantities and smaller sizes of the melee diamonds. A comprehensive pilot test program was successfully conducted with one of Rubel & Ménasché suppliers of high-quality melee diamonds. This pilot tested the solution’s feasibility and effectiveness across varied diamond types and manufacturing processes, validating its potential to streamline melee traceability cost-effectively.

Joey Lager, Rubel & Ménasché CPO, stated: “The introduction of a scientific traceability solution for melee diamonds is an important milestone. Our successful collaboration with Sarine is testament to this, and I am convinced of its transformative impact on the industry.”

Sarine’s CEO, David Block, emphasized: “This initiative reaffirms our commitment to a more transparent diamond industry. We are dedicated to providing data with the highest level of assurance, enabling the industry to offer reliably sourced and manufactured sustainable products, ensuring a viable future. It is a pleasure to collaborate with partners such as Rubel & Ménasché, sharing a common vision of transparency and excellence.”

ABOUT SARINE TECHNOLOGIES: Established in 1988, Sarine Technologies Ltd. is a worldwide leader in the development and manufacturing of advanced modeling, analysis, evaluation, planning, processing, finishing, grading, and trading systems for diamonds. Sarine products include the Galaxy® family of inclusion and tension mapping systems, rough diamond planning and optimization technologies, laser cutting and shaping tools, laser-marking, inscription, and fingerprinting equipment, automated (AI-derived) Clarity, Color, Cut and light performance grading systems and traceability, visualization and retailing services. Sarine systems have become standard tools in every modern manufacturing plant, properly equipped gemology lab and diamond appraisal business, and are essential aids for diamond polishers, dealers, and retailers. For more information about Sarine and its products and services, visit http://www.sarine.com.